The Ultimate Guide to Fixture and Jig

Fixtures, as well as jigs, are both made use of to lower the non-production time of the mass production process and are commonly made use of as basic synonyms for every other. Functionally, they are different devices. What’s the difference between a jig and also fixture? Fixture vs jig, take a look at the contrast involving the meaning, types, applications, the way of working, functions, and more aspects.

What is a Fixture?

The fixture is a job holding tool used to securely locate, install the component and also support to be machined with the machine in the right setting, to make sure the work surface repaired in the fixture can keep consistency and interchangeability. What varies from jig is it never ever overviews the device.

Sorts of Fixtures

Based upon the procedure to be carried out, fixtures can be separated right into turning fixtures, milling fixtures, grinding fixtures, broaching fixtures, drilling fixtures, tapping fixtures, welding fixtures, and assembling fixtures.

Fixture Utilizes or Applications

Fixtures are commonly used in milling, turning, planning, slotting, grinding, and also various other multidimensional machining procedures, as well as automobile setting up as well as optical, laser scanning inspection. The material block clamped inside a CNC machining, the vice on the workbench is likewise a fixture. Fixtures are also important in an auto assembly line to secure and assist cars and trucks via the welding and also assembly process.

What is a Jig?

The jig is a type of custom-made job holding tool used to regulate the area as well as the movement of parts as well as various other devices, in the CNC machining process, a jig commonly finds and also holds the workpiece in an appropriate placement and overviews the cutting device to do a particular operation, to maintain right connection in between the work and also cutter. When the jig steps, the tool continues to be stationary. The machining part normally is protected in the jig by securing.

Sorts of Jigs

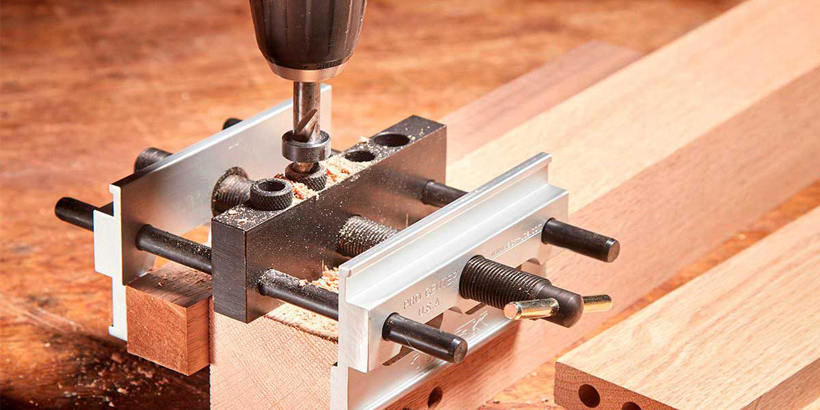

The most usual type of jig is drill jig, which is used to direct the drill a little bit for producing openings at detailed locations. Examples of drill jigs are box jig, angle plate jig, sandwich jig, and also channel jig. Woodworking jigs are likewise widely made use of for developing elaborate wood profiles. There are likewise various other sorts of jigs including design template jig, plate jig, diameter jig, ring jig, indexing jig, welding jig, jeweler jig, and extra.

Jig Utilizes or Applications

Jigs are usually made use of in boring, reaming, counterboring, tapping, and also another one-dimensional machining, or applied as overviews for devices or design templates in other industries, like furnishings, unique cramping jigs that make certain squareness are commonly set up. Pierce bushing is one more usual application for a jig, which assists guide a drill a little bit via the surface of the machining component for ideal positioning as well as angle.

Distinction Between Fixture and Jig

Both fixtures, as well as jigs utilized for machine devices, can minimize job time and also boost efficiency. Component vs jig, what are the distinctions between the fixture and also jig?

Complexity

Jigs are generally simpler to use, while fixtures are kind of challenging and might need some skills and also devices for the operation.

Whether fitted to machine

Jigs are not fixed to the table, and also can be held by hand without securing in machining, they can likewise be secured for hefty work, and also it does not require any kind of extra gadgets, while components are constantly clamped firmly on the worktable of CNC machining, and also requires accessories like blocks or evaluates to move the reducing tool precisely.

Main Function

The jig is largely made use of to assist the movement of cutters repeatedly at predefined areas on the job, and also support and also locate the component. The fixture is mostly used to safeguard, sustain and situate the workpiece and also keep fixed positioning, not direct the cutter.

Weight

Jigs are commonly lighter in weight for quicker handling, while fixtures are usually much heavier and also needed to endure cutting pressure and also resonance.

Cost

Jigs are usually more costly than fixtures.

Style

The construction of the jig is usually made more complex while the fixture styles are simpler.

Just how it is utilized

Fixtures are normally made from grey cast iron or steel parts by welding or bolting, jigs typically make use of basic components like bushes and also screws.

Whether contact with a cutting tool

Fixtures do not directly speak to a reducing device, it’s designed to fit a specific component individually. But jig can be found in contact with the tool to establish the angle and position precisely.

CNC machining applications

Jigs are commonly utilized in drilling, boring, reaming, and also tapping, while components are embraced for milling, slotting, shaping, transforming as well as planning.

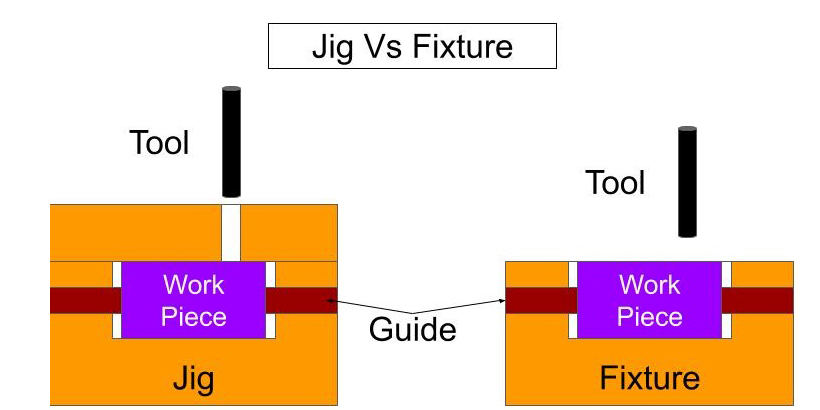

You can use jigs and fixtures with each other to obtain the required accuracy and objective. We can see the fixture and also jig difference in building and construction straight from the following figure. The left one is a jig as it has a hole to assist the device, while the right u-shape body is a fixture as it is simply holding the work surface.

Exactly how fixtures and jigs are made?

CNC machining services is a flexible manufacturing process to produce jigs and components with created forms and requirements. Not all fixtures and also jigs are made of metal, plastics are additionally feasible.