Tips For Make Sure The Machining Process Efficiency Of Precision Parts

High precision parts used in various markets of testing devices- scientific instruments, mostly made use of in domestic scientific instruments. In the instrument market, precision elements factory offers components handling, require to take into consideration the corresponding technology as well as performance, as well as detailed procedure. Just how to make sure the factory handling performance of precision components and just how to do precision components refining well? Allow’s take a look at the adhering to guide.

How To Guarantee Machining Efficiency Of precision Components

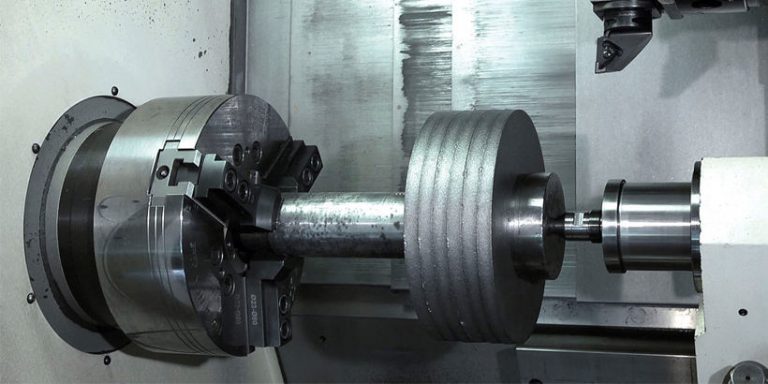

- Laborious, rough finisher to ensure machining accuracy. The features of rough machining, as well as finish machining, are various. Rough machining and finish machining should be carried out separately, and also the handling conditions should be purely managed.

- Select suitable processing equipment. For finishing and also rough machining, they have various requirements for devices. In the rough machining process, we can choose high-precision device devices, yet in finishing, we require to choose high-performance machine tools.

- Do precision components processing heat treatment actions. The application of this process has a high impact on the handling quality, which should be paid attention to.

However, with the right to enter the clinical technique of precision components refining job to satisfy the expanding demand of business, will aim to boost. So, just how to do a great job in precision components processing?

How to do a great job in precision components processing?

In order to ensure the machining accuracy of precision components, the great and also coarse mechanical components are refined well respectively.

Because when rough equipment parts, cutting quantity, cutting pressure of workpiece, clamping force, warm, surface hardening of mechanical parts, substantial, big inner stress and anxiety in the work surface, if rough, rough handling is completed continually, the mechanical parts after precision will soon lose stress redistribution. It is made use of for machining some machined parts with high precision. Roughing as well as completing, or ageing therapy must be organized after reduced temperature level annealing to remove inner tension.

Choose the equipment reasonably

Rough machining of mechanical parts is mainly to remove most of the machining allowance, and also it does not need high-precision machining of mechanical components, so rough machining should be high-power and high-precision maker tools. In the process of conclusion, abide by using relatively high-precision machine devices. Rough, finished on different machines, can offer full play to the equipment capability, and can expand the service life of precision equipment tools.

Heat treatment is usually arranged in the process of precision parts processing

Location is as follows: Heat treatment to boost metal cutting performance, such as annealing, normalizing, solidifying, embedded in the treatment of general mechanical parts. In order to boost the mechanical properties of the parts, such as carburizing, quenching and tempering, the mechanical components are usually set in the above therapy. If the contortion is big after heat therapy, the procedure after processing must be organized.

It is essential to use a great modern technology at this time, that is precision components processing, precision parts handling. As long as you refine your parts as well as tell them that what you need is part of the courteous words, you can obtain the components you desire to satisfy in the machine.