Top 7 Design Tips for CNC Machining Parts

CNC machining can produce tailored get rid of good strength and tight resistance as well as it’s good for mass production. Actually, CNC machining is currently one of the most reliable approaches for producing metal prototypes.CNC machining is commonly used in many fields due to the benefits. You need to recognize exactly how a CNC machine works before making CNC machined components.

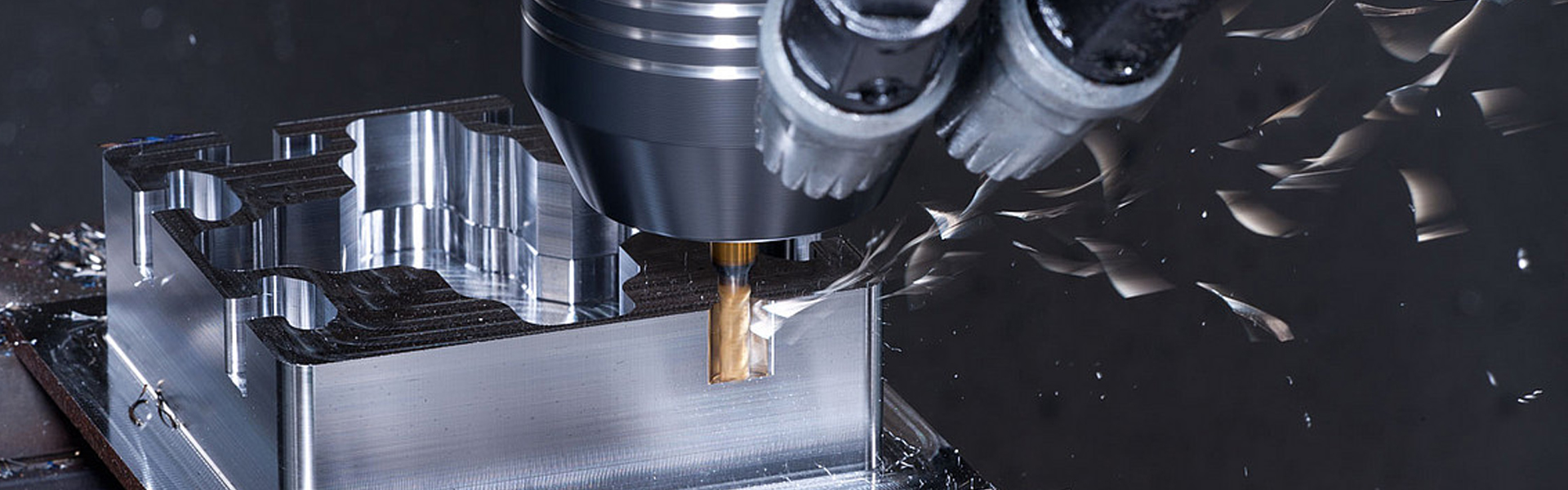

CNC Machining

A strong block’s product is removed by reducing devices that rotate at high speed in order to make the desired part according to the drawing. The cutting device plays a vital function in CNC machining, which straight touches the component as well as eliminates the extra material to have actually the wanted component.

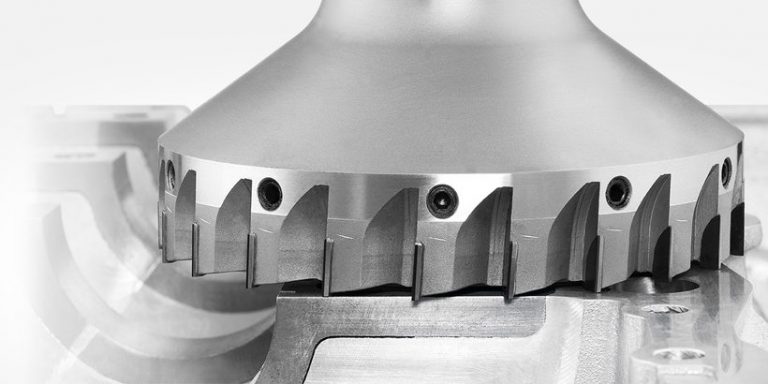

One of the most common CNC reducing tools such as the completion mill tool as well as drill has a round shank with a certain form of cutting suggestion as well as a limited cutting length. Both attributes of reducing devices make the cutting capacity have a constraint. Internal upright rectangular corners can be made as a result of tool geometry. Deep tiny openings and also undercuts can not be processed by CNC machining due to cutting size.

Tips For CNC Designs

There are some beneficial pointers for CNC designs in order to take good advantage of CNC machining.

Including a Span in the Internal Vertical Edge

The CNC milling device has a cylindrical form. When the interior wall surfaces are reduced, a radius will occur on the upright edge. Edge radius will be reduced by a tool with a smaller diameter, yet you can’t produce an interior upright corner no matter what kind of tiny device you use. Tiny tools can work numerous passes at reduced rates to achieve a small distance, which will certainly trigger even more time and also greater price. Consequently, when you create a component made by CNC machining, it’s much better to include a one 3rd radius of the deepness of dental caries and also use a similar radius for inner edges.

Restricting the Depth of cavities

The devices function effectively when they cut cavities with a depth approximately 2-3 times of their sizes because of the minimal reducing length. Milling tooth cavities with deepness over 4 times of sizes of devices can substantially boost machining troubles as well as tool damage, causing high machining expenses. Develop the pocket with a depth of fewer than four times the device size if it’s possible.

Enhancing the Density of the Thin Wall

It’s challenging to machine the thin wall as a result of its deformation or crack in the CNC machining. The thin wall surface machining requires several passes at reduced cutting depths, as well as vibrations easily happen. For that reason, it’s tough to accurately equip the thin wall surface and the machining time will certainly be raised. It’s better to design the wall for 0.8 millimeters for metal components and also make the minimal wall density greater than 1.5 millimeters for plastic parts when possible.

Restricting the Size of Threads

People have a tendency to believe that the longer the strings are, the more powerful the link ends up being when it pertains to the size of threads. As an issue of the fact, the size of the hole does not really contribute to the strength of the link when threads are longer than 1.5 times. As a result, it is much better to develop threads with a minimal size of 1.5 times and also a maximum size of 3 times the hole size in order to have a great fastening.

Specifying Resistances just Needed

The machined part which needs more accuracy will add even more cost to CNC machining as a result of the more machining time and also labor cost. Resistances should be specified meagerly when it is essential.

If a certain tolerance isn’t required on the technological illustration, after that the component is mosting likely to be machined with a basic resistance of ± 0.125 millimeters, which suffices for several non-critical alternatives.

Minimizing Little Attributes

Small features such as micro-holes which are less than 2.5 millimeters in size can cause machining difficulty and machining time, so they should certainly be prevented unless they are actually required.

Selecting Design with Engraved Text

It is better to pick the engraved message compared to the embossed message when a message is needed for CNC machined parts. The personalized message needs removing much fewer materials. It is recommended to make use of a Sans-Serif font style such as Arial and also Verdana with a size of a minimum of 20 factors. A lot of CNC machines have pre-programmed regimens for these font styles.

It is suggested to develop parts that can be machined in as few configurations as possible and better in only one setup. For instance, a component that has blind holes on both sides needs to be machined in two configurations, due to the fact that it needs to be revolved to obtain access to every side. Much less arrangement will certainly reduce the re-aligning time of the component as well as make the machined components more precise.