Top 5 for the Most Common Machining Technologies

CNC machining involves a variety of technologies incorporated with computer numerical control, to produce a designed part with machine tools. To obtain the needed form or function, in some cases certain CNC machining process is needed in production. Below let’s obtain an understanding of the most common CNC machining techniques.

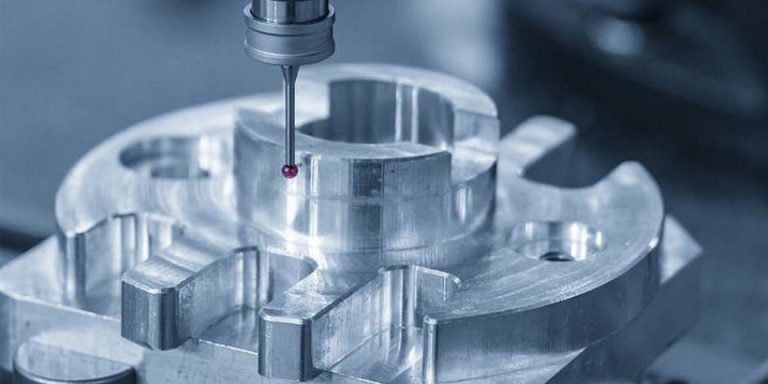

Boring

Boring is a machining technology to increase the size of an existing hole in the metals or various other material, which often performs after other procedures like drilling, the general function of boring is to obtain more precise dimensions and dimensions of the hole. A special cutting tool with a curved pointer will press via the cut hole in the rotating workpiece.

Reaming

Reaming is a machining technique that rotary reamer to remove mini metal layers from the hole wall surface of work surface, to enhance the dimensional precision and also surface high quality of the hole drilled because some of the material perhaps left in the red. For little as well as accuracy holes, reaming is a practical and economical procedure.

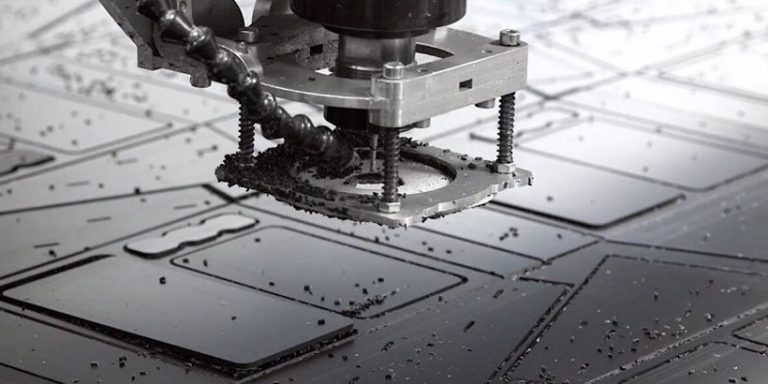

Milling

Milling is a common machining procedure that makes use of a revolving milling cutter with a number of blades (cutting edges) to cut the stationary block product and also develop different surfaces. Milling consisting of peripheral as well as face milling.

Turning

Unlike milling, turning is a machining operation that the cutting tool to get rid of material from a revolving workpiece kept in a chuck on its axis, for producing a particular form. The turning cutter is generally a non-rotary little bit. Lathes are the most typical turning machines, the lathe can additionally be utilized for the handling of drills, reamers, taps, dies and also knurling tools, to produce shafts, pins, bushings and also various other work surfaces with rotating surfaces.

Drilling

Drilling describes the procedure of drilling holes on strong materials with a drill, among the most usual machining methods, the drill bit that placed straight against the product can create hundreds and even thousands of rotations per minute. CNC drilling machine is mostly utilized for exploration, reaming, chamfering and also another handling, used in automobile, mould, aerospace, building as well as shipbuilding machinery industries.

There is likewise a huge selection of common machining technologies, CNC brings automated operation, unprecedented performance and also precision, as a professional CNC manufacturing company, DEK can supply customized CNC machining services for you.