Guide to CNC Lathe

CNC lathes are changed and developed from the conventional lathes with the Computer Numerical Control technology, and also originated from a variety of kinds. As a personalized CNC turning manufacturer, DEK will certainly present how does CNC turning lathe work and also what types of CNC lathe machines are made use of.

What is CNC Lathe?

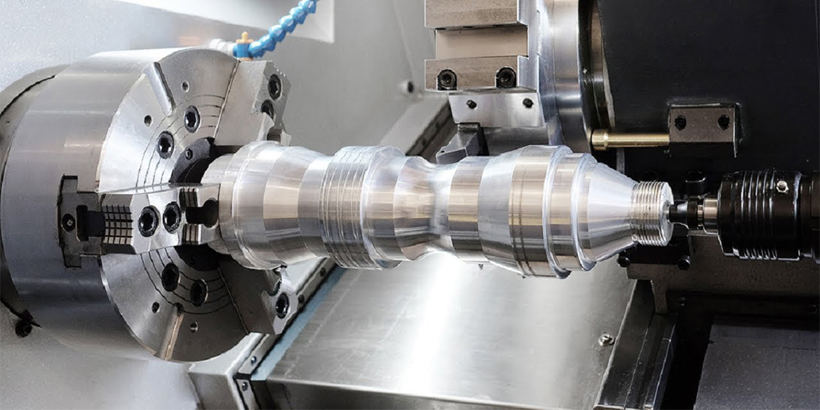

A CNC lathe is computer-controlled machinery mostly for CNC turning services and also procedures, including tapered turning, hard turning, spherical generation, facing, parting, knurling, drilling, grooving, etc. These procedures can be executed like traditional lathe machines, while CNC turning lathe is created to use modern-day technology as well as tooling to improve the productivity and also high quality of CNC turning components.

Benefits of CNC lathes

- Stronger capacity

- Higher precision

- Improved efficiency

- Shorter turn-around time

Parts of CNC Lathes

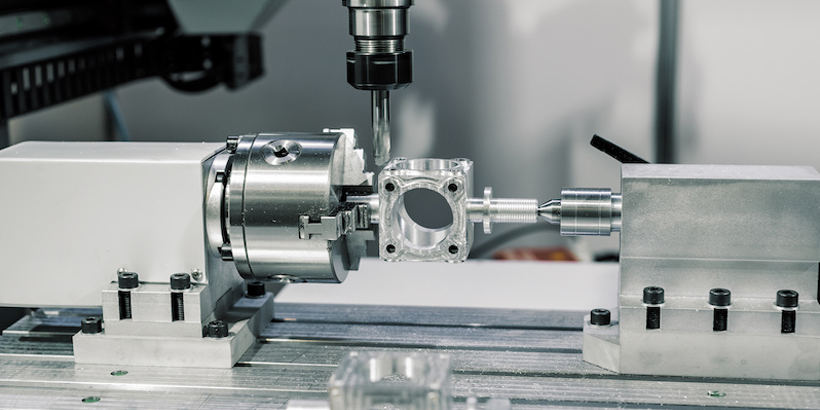

Different kinds of CNC lathes will various configuration, however, a CNC turning lathe is generally made up of numerous of the following parts: machine bed, main spindle, sub-spindle, chuck, overview way, headstock, tailstock, tool turret, monitor, carriage, CNC control panel and also drive motor.

Modern CNC lathe machines are often mounted with real-time devices that can operate in numerous axes, like both the X and Y-axis, a second turret with various tools, and much more.

How Does CNC Turning Lathe Work?

CNC turning lathe is used to generate specific turned parts with round or cylinder shapes, the ended up product is complete, as well as does not need a second operation on other CNC machining equipment. The CNC controller works with the drive motor and also make numerous components interact as well as move the shaft to complete designed motion according to the CNC programs.

- Check out whether there is any faults as well as abnormal situations, make troubleshooting.

- Upload the G-Code computer system data to the CNC lathe.

- Install a cylindrical material block as well as protection in the chuck.

- Establish the spindle at the required rate, after that to turn the chuck and workpiece.

- Check the rotating workpiece and spindle speed, make sure there is no discrepancy.

- Move the device turret and also carriage to locate the cutting device as a specific feed.

- Move the carriage to perform the cutting operation, eliminate all excess materials to obtain the final CNC lathe component.

Kinds Of CNC Lathe Machines

As the typical CNC turning machine, lathes can be categorized as various standards.

Based upon the variety of axes

- 2-axis CNC Lathe: can do outer/inner size machining, encountering, boring and tapping.

- 3-axis CNC Lathe: X and Z axis, C axis and live tool system, allowed to carry out milling, boring, and so on.

- 4-axis CNC Lathe: include Y-axis based upon 3-axis device, for off-centre machining operation and also an intricate component.

- 5-axis CNC Lathe: add a 2nd turret, allows two tools to work at the same time.

Based upon the job demands

- Speed Lathes: basic style, composed of the tool, headstock as well as a tailstock blog post, can run in three and also 4 rates.

- Engine Lathes: most typical lathe machine, can run with varied metals at a large range of speeds, length as much as 60 feet.

- Turret Lathes: several sorts of tool owners can be placed on it.

- Tool Room Lathes: create get rid of great precision as well as finishing.

Based on the placement of the lathe spindle

- Vertical CNC lathe: the turret spindle is perpendicular to the horizontal, with a huge size circular table used to clamp the workpiece.

- Horizontal CNC lathe: can be split right into flat guide rail CNC lathe and angle guide way CNC lathe, the angle overview method framework can make lathe extra rigid as well as easy to discharge chips.