What Cause To Overflow Of Injection Molding Machine Head and it’s solutions

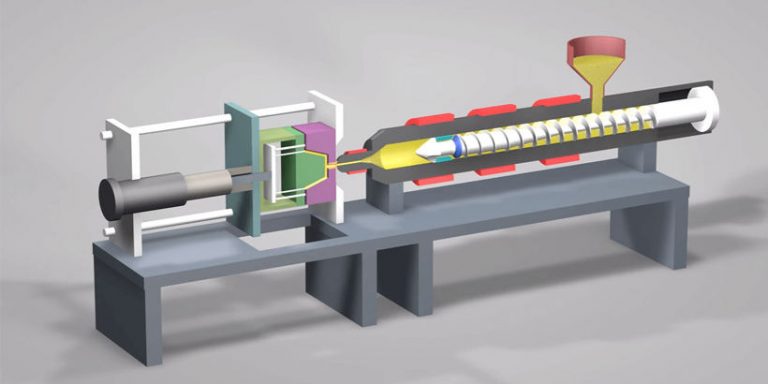

The injection mold machine is the main molding tool for thermoplastic or thermosetting plastics, as well as it uses plastic molding dies to produce a wide range of plastic products. Throughout injection molding, it might occur overflow of injection molding machine head for some factors, which is also known as blinking, overflowing side, drape as well as so on, mostly happens in the mold closing position. The overflow of the insert gap and ejector hole will certainly additionally make the item stuck on the mold and mildew as well as affect the demoulding.

Mold aspect

- Foreign issues are tarnished on the parting surface or sticking out skid printing burr is found around the mold framework. The old mold was fatigue collapse around the cavity due to the earlier extrusion of the flying side.

- The mold layout is unreasonable. The opening position of the mold and mildew cavity is as well prejudiced, which will trigger the tension on one side of the mold throughout injection, which will certainly cause the flying edge.

- The plastic fluidity is as well excellent, such as polyethene, polypropylene, nylon, etc., the thickness is very low in the molten state, and also it is simple to enter the set or movable space, so the manufacturing accuracy of the mold is required to be high.

- On the premise of not influencing the integrity of the product, it must be put on the facility of top quality symmetry as long as feasible. The thick part of the item is fed to stop the circumstance of the missing product as well as the flying side. When there are creating holes in the center or near the item, a side gate is generally opened on the hole. Due to the fact that under the big injection pressure, if the mold and mildew closing force wants, the sustaining force of the mold and mildew in this part is insufficient and also a little buckling will take place, which will certainly trigger the flying side. If the side of the mold has movable participants, the projection location of the side is likewise impacted by the forming pressure, as well as if the support is not nearly enough, it will trigger the flying side.

- The precision of the sliding core is not good, and the balanced out of the fixed core and the dental caries instalment placement will certainly also generate the flying edge. The exhaust of the dental caries is poor, and there is no exhaust ditch on the parting surface of the mold, or the exhaust ditch is also superficial, or unfathomable or obstructed by foreign matters, which will certainly create the side to fly. For the multi-cavity mold, the practical layout of the gate of each shunt channel must be taken note of, otherwise, the uneven pressure of the filling mold will certainly be created and also the flying edge will certainly be created.

Process

- The injection pressure is expensive or the injection speed is also fast. The boost of opening pressure on the mold and mildew leads to overflow due to the fact that of high stress and also high rate. According to the thickness of the product, the injection speed and also injection time should be adjusted. The thin items should be full of high speed and also fast mold, and also no injection will be made after filling up. Thick products ought to be full of reduced speed mold, and also the skin should be repaired before the final pressure is gotten to.

- The excessive charge causes the flying edge. This situation must be fixed by lengthening injection time or holding time.

- The heat of barrel and also nozzle or too expensive mold and mildew temperature level will trigger plastic viscosity to lower and enhance fluidness, which will certainly create flying edge when streaming into the mold and mildew smoothly.

Equipment

- The real mold closing force of the equipment is insufficient. When selecting an injection molding machine, the rated mold and mildew closing force of the equipment must be more than the stress developed by the longitudinal projection area of injection molding items throughout injection, or else, the mold development will take place and also flying edge will certainly occur.

- The modification of the mold closing gadget is not good, the arm joint bar device is not straightened, the left and also right or the top as well as reduced closing mold are not well balanced, as well as the similarity of the mold can not be gotten to causes the situation that side of the mold is snugly closed and the opposite side is not firmly affixed. The flying edge will certainly show up throughout injection.

- The inadequate similarity of the mold and mildew itself, or the non-identical setup, or the non-parallel formwork, or irregular pressure distribution and also contortion of the pull rod, will certainly cause the mold closing not close and also create the flying edge.

- The check ring is significantly worn, the springtime of spring nozzle stops working, the wear of the material barrel or screw is also large, the failing of the air conditioning system at the feed port causes the phenomenon of “connecting”, the insufficient billing quantity of the barrel adjustment and also the as well small barrier pad might cause the flying side to happen continuously, as well as the components must be repaired or replaced in time.

Raw material

- If the viscosity of plastics is reduced, such as nylon, polyethene, polypropylene, and so on, the mold bonding pressure must be boosted; The plastic with solid water absorption or water delicate plastic will greatly reduce the flow viscosity as well as enhance the opportunity of flying side under high temperature. If the viscosity of plastic is also high, the flow resistance boosts, and also the backpressure will increase the pressure of the mold cavity, which will cause the inadequate closing force and the flying side.

- When the dimension of plastic raw materials is unequal, the quantity of feed will alter, the parts or frustration, or the flying edge.