Tips For Obtaining CNC Parts

Modern companies can be divided into two large teams. Production and also solutions. Due to the fact that it is simpler to begin a company doing some kind of solution based on your education or abilities, the second team is significantly bigger. You can establish a coaching firm or a freelance composing organization with little to no financing. Production services have it a lot harder. To generate CNC parts you require to recognize a whole lot. Your potential is much higher. The manufacturing needs much less time and can grow into something possibly larger than a solution company as soon as you have actually set whatever up.

We have chosen to make this simple step-by-step guide for you to see that obtaining components by CNC machining is not as gruelling as it sounds which there are means you can make it even easier on your own.

You normally start by picking what to produce. Think me, there are lots of ways to boost our life or to bring more amusement to it. Also producing mundane things can be terrific if you have your distinct angle that the customers like attractive. We are not mosting likely to assist you with what to generate however rather exactly how to do it. So, proceed to the following step as soon as you have actually selected what to sell.

Layout Idealized CNC Components

So, whether you have or have not established a machine shop to deal with, Your initial task is to design what you wish to create. At this phase do not bother with the manufacturing capabilities excessive, you can mind the optimum dimensions however at this phase let your creativity flow. You should start by providing the attributes with your item will have. Then, draw an illustration that will certainly lay out the basic layout and also the working concepts of your suggestion. After that, I recommend you decide on the main dimensions and also start making a 3D model of your style. 3D modelling has actually been adopted and is really simple nowadays. There are tons of totally free lessons on the net.

CNC Machine Shop Requirements

To start with, you need to recognize that you are creating a get rid of the intent of manufacturing. It means you will certainly have to take the manufacturing limitations into account. Preferably, you ought to recognize where you are going to generate the part so you can estimate the opportunity of production. You can create the parts and after that look for the supplier yet it is feasible you’ll need to additionally upgrade your item to ensure that the chosen machine shop can generate it. My recommendation is that you decide on the manufacturing facility expense, of training course, preferably, you acquire equipment to produce your components and also established up a factory however extremely few people have the money for it. Therefore, you will certainly be searching for a suitable CNC factory.

What should you consider?

- Make note of the materials they collaborate with, the much more the better.

- Look at the mass and also max measurements of the components they can make.

- Check out finishing procedure possibilities. A lot of individuals have to try to find a 2nd look for anodization or sprucing up.

- Look at the accuracy of their devices. It has to be 30% more precise than the tolerance of your parts.

- Take a look at the variety of various device tools they have. Look at the amount of each kind. You might need to increase your production at some point.

As soon as you’ve selected the machine shop you intend to work with, obtain as much info on their CNC machining for components and prototypes abilities and also write it down. When you develop your item, maintain it at hand.

Change Design For Manufacturing CNC Parts Demands

As soon as you’ve made your excellent view on the product, the following stage is, sadly, to cut and also dice it a little bit. You need to get this sheet of Information regarding your CNC machine shop, locate some production recommendations short articles for CNC machining, and also start assessing your style. This stage is one of the most vital if you get to serial production since let’s state you made a modification in the style that lets you conserve one cent in production expenses, be it time or devices or equipment utilized. Let’s say you generate 2000 products a month, that is 24000 a year, so, you will save $2400 a year if you enhance your design by a solitary cent. Consider additional possibilities. The, even more, you create the more scrupulously should you look into your style? There are some devices in further actions that can help you make your design a lot more manufacturable.

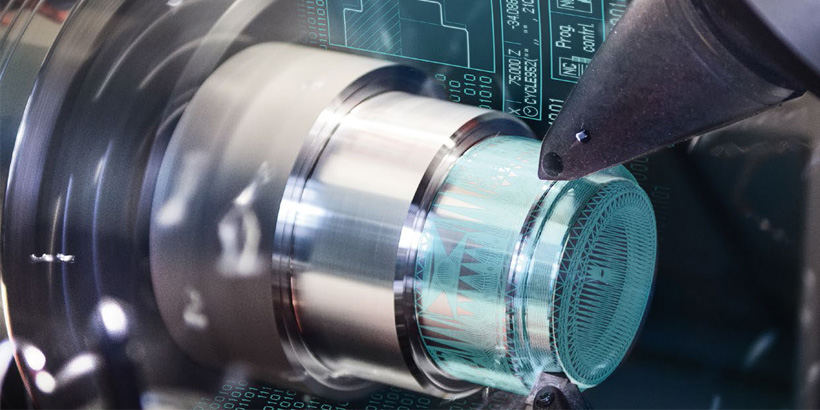

CNC Programming

The result of the design is a 3D model as well as a technical illustration representing all its dimensions as well as tolerances. From there on, if you select making a prototype yourself, you’ll need to find out CNC programs. The majority of CNC device tools make use of a unique programming language called G-code. The component is positioned in a coordinate system of the equipment device and also each line tells where the cutting device needs to relocate.

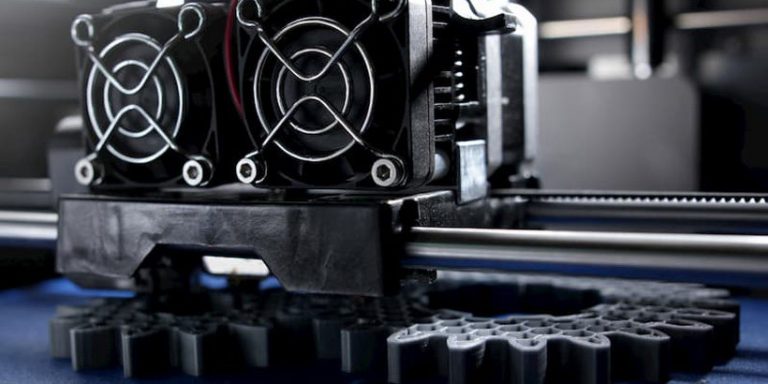

You can additionally make use of a CAM system to aid you to develop an NC program. Then, you’ll have to pick, which surface area on your CAD version need to be machined as well as the CAM system will certainly generate the code itself. This stage is quite complicated because you ought to consider the geometry, the resistances, and also materials to generate a great program. We suggest that at this stage, you employ a good machine shop. Models are not pricey nowadays as well as professionals will move your task to the next step that much quicker.

Program Proofing

You need to test out the program once you’ve done all the preparations. First of all, a great deal of CNC systems has a virtual simulation attribute that allows you to see the reducing progression on the screen of the tool. By doing this, if you’ve done any blunders, you will certainly see them without harming anything. We suggest you test out the NC program on a softer material once you’ve checked that. If an accident occurs, the cutting devices and also tooling will not experience damage.

CNC Machine Setup

When you have the program, it is time to establish the part. A standard CNC equipment setup includes the following considerations:

- Part positioning. During the previous step as well as this, you’ll need to select the series of component positionings to erase all the excess material.

- Part securing. Because the cutting forces will try to eliminate it from its setting, you require to securely hold the part in the area. There are a lot of different kinds of components to clamp the part. We highly recommend making use of basic tooling sets of components and jigs, nevertheless, if your part has a complex form, you may require to buy unique tooling. Some machine shops specialize in Quick Tooling perfect for tiny sets and prototypes. It is less expensive and is made faster.

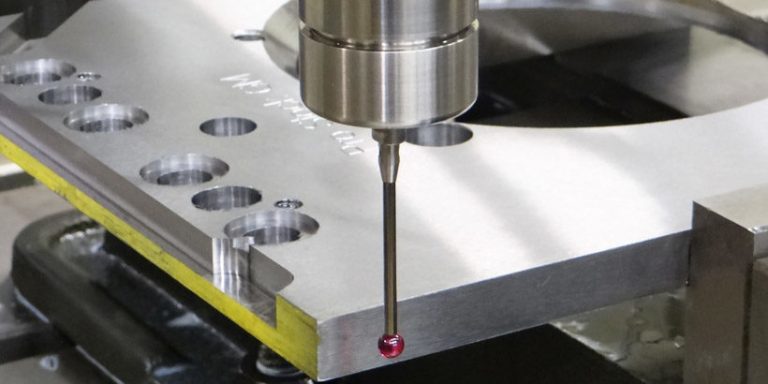

- Coordinate No. When you have actually secured the part, the machine tool needs to understand where absolutely no coordinate is located. You can either manually adjust this point by touching the work surface with a device and computing the difference by hand, or you can buy a special sign.

- You need to position all the tools you use in your NC program in the designated slots (you should check that the tools correspond to the numbers in the G-code). You have to manually insert the dimensions of the tool so that the machine knows how long and wide it is.

Quality Control

Once the part is complete, you need to inspect, whether it meets all the style requirements. If your CNC component has high precision, you’ll need unique devices and also quality assurance techniques.

Machining The Component

It is time for the machining CNC parts once you’ve checked and double-checked the NC program. This component is generally simple for prototypers given that you just manufacture a couple of parts as well as there are no strict timing intervals for part loading and also dumping. However, when you make parts, you require to focus on those points and reduce established times as much as feasible.

Surface Finishing

CNC components finishing is extremely vital due to the fact that it adds to the visual appeals of your item and also more significantly, its resilience. Sure, metal sheen looks great on a fresh machined part but it will grow dull, as well as corrosion, will set in an issue of weeks. If you have specific equipment, there are Lots of Finishing Techniques available. We suggest you contact the professionals if you want your part to look great. If you do not need the ideal surface, for now, repainting the get rid of a brush is always a choice for a low-cost option, however, we strongly advise that you do not abandon ending up.

Does DEK Can Deal Costs CNC Components

At DEK, we can provide rapid prototyping, CNC machining, fast tooling, and also a lot more. Our customer care designers will examine your layout for manufacturability(DFM) to assure that the component can be made past your expectations. Lean low volume manufacturing, fasting delivery, as well as total after-sale service, you can obtain the best components as well as models there. If you wish to know more concerning us, please don’t be think twice to contact us.