Guide to Flow Lines In Injection Molding

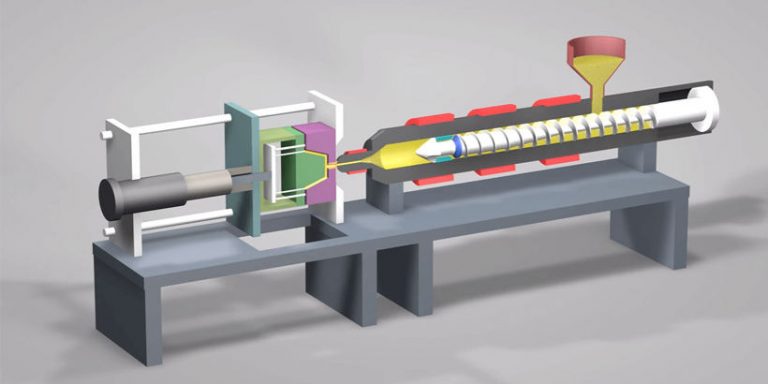

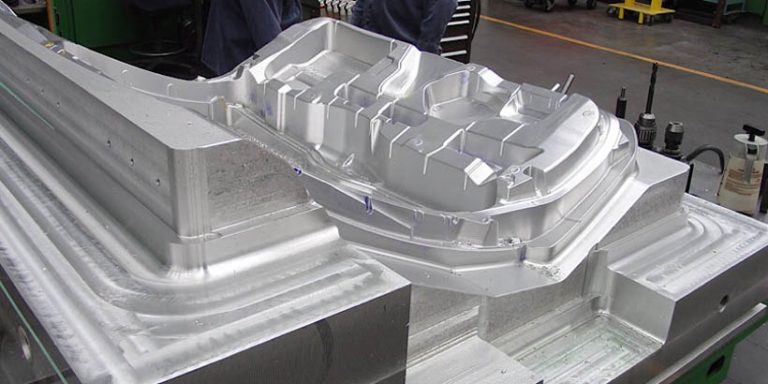

The flow line is usually connected to injection specifications, mold and injection material, it can be defined as linear grooving, or round surges, on the surface of an injection molded part that shows the instructions of product flow within the cavity of the mold. In this guide, we cover evaluation and also the remedy of flow lines in injection molding.

Common injection Mold Flow Lines

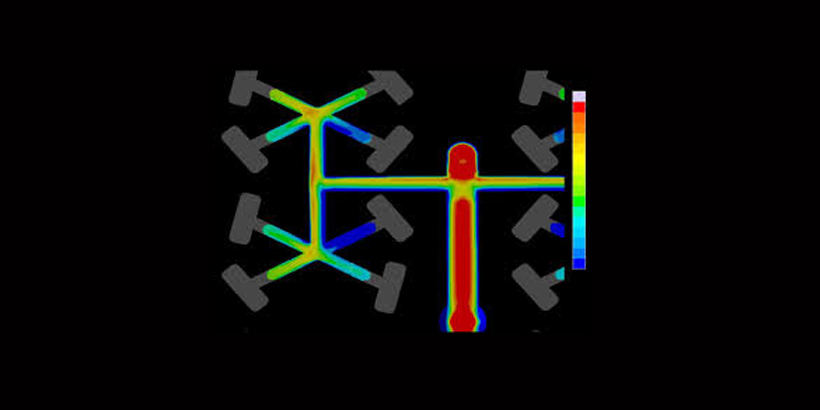

- Radiation lines- Normally, it just shows up near the gate. When the thaw goes into the mold dental caries, it will certainly produce a jet, which is revealed as radiation externally of the product, so it is called radiation line.

- Fluorescent lines- The shear stress created by thaw flow makes the surface of the item produce appeal very similar to that of the firefly body, so it is called a fluorescent line.

- Snake lines- When the melt goes into the mold cavity from the gate, it creates a jet result as well as appears like a snake on the surface of the product, so it is called a serpentine flow line.

- Wave lines– The Flow of the thaw in the mold cavity is not smooth, in some cases fast and in some cases slow. It is like waves on the surface of the item, so it is called the wave line.

Countermeasures to Injection Mold Flow Lines

Radiation Lines

When the injection price is too expensive as well as the melt is expelled, due to the flexibility of the melt, when the thaw flows rapidly from the barrel via the mold gateway to the mold tooth cavity, the flexible recovery of the melt is too quick, resulting in the thaw fracture and radiation.

Countermeasures:

- Modification of the process problems. High pressure, as well as reduced speed injection, can boost the flow time of the flexible melt in the same flow length, raise the degree of elastic failing, and reduce the incidence of radiation.

- Modification of the mold gate form. By increasing the gate or altering eviction to fan-shaped, the flexibility of the melt can be a little brought back prior to it enters the mold cavity to prevent melt fracture.

- Before the melt goes into the mold dental caries, the elastic failure of the melt can be avoided.

- Extending the Flow course of the thaw before the mold dental caries can enhance the level of elastic failing of the thaw as well as prevent the incident of radiation lines due to the melt fracture.

Fluorescent Lines

When the melt flows in the mold cavity, one end of the molecular chain near the solidification layer is chosen the solidification layer, and the various other end is extended along the Flow direction by the surrounding molecular chain. Due to the fact that the flow resistance of the melt near the cavity wall surface is the largest and also the flow price is the tiniest, while the Flow resistance at the facility of the cavity is the smallest and also the flow price is the biggest, so the velocity gradient is created in the flow direction.

When the injection price is small, the injection pressure is high or the density of the product is thin, the sheer pressure of the melt near the dental caries wall surface is the toughest and the orientation degree is the biggest, The polymer shows interior stress when it is stretched in the Flow, which leads to the look of fluorescent lines on the surface of the product.

Countermeasures:

- Change the procedure conditions. With the boost of injection rate, the cooling time of the thaw in the same Flow size decreases, the solidification of the melt per unit volume is reasonably slow-moving, the internal tension of the product is compromised, and the look of fluorescent lines externally of the product is decreased.

- Enhance the mold temperature level. Compared to the mold temperature, the leisure of macromolecules is increased, the molecular positioning, as well as internal tension, are decreased, thus decreasing the look of fluorescent lines externally of items.

- Modification of the cavity framework as well as boost the item density. The results reveal that the thickness of the item is larger, the thaw cooling is slower, the tension leisure time is longer, the orientation stress is lowered, and also the fluorescent lines are minimized.

- Warmth treatment (stove warm or baking water boiling). The warmth treatment makes the macromolecular motion escalated, the relaxation time reduced, and also the depolarization impact reinforced, so minimizing the fluorescence lines.

Snake Flow Lines

When the deepness of eviction is a lot smaller sized than that of the dental caries entryway, and the filling up price is extremely high, the thaw flow comes to be unsteady jet flow, the front jet has solidified, as well as the back moving thaw fills the cavity, and also the serpentine Flow pattern will show up on the surface of the product.

Countermeasures:

- Modification of the process problems. By minimizing the injection rate, the jet impact will be gradually eliminated, and the thaw flow setting will certainly be increased, as well as the increased flow will certainly make the item have much better surface area top quality. In addition, increasing the mold temperature level and also thaw temperature level will certainly likewise reduce the jet impact as well as expand the melt flow.

- Adjustment of the mold gate dimension. When eviction deepness is a little smaller than the cavity depth, the jet growth makes the melt behind merge with the front edge of the jet not far away from the front, so that the jet effect is not evident. When the gate deepness is equal to or close to the cavity depth, the mold filling rate is reduced as well as the spreading flow is created.

- Adjustment of the mold gate angle. The angle between the mold entrance as well as the moving mold is 4O ~ 5O, to make sure that when the melt drains from eviction, it will become by the mold cavity wall surface initially, which can avoid the look of serpent Flow.

- Modification of the mold entrance placement. When the mold gateway is evaluated the closest position to the mold dental caries wall surface (perpendicular to the instructions of the gate), when the melt drains from eviction, it will certainly be stopped by the mold cavity wall first, which can also avoid the emergence of jet Flow and also make it become extensive Flow, so as to stay clear of the appearance of the snake flow line.

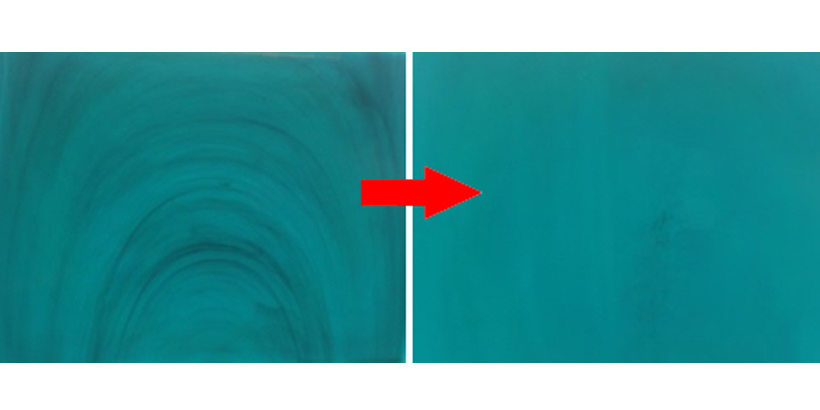

Wave Lines

In the procedure of melt loading, the brand-new thaw flow is continually pressed out from the internal layer, which drives the front wave to move and stagnate. Specifically in the case of high injection rate, reduced injection stress or unreasonable mold framework, the thaw flow in and also out, and also PP formation in and also out, it is more most likely to trigger the surface crystallinity of the item is inconsistent, forming curly lines on the surface area of the item.

Countermeasures:

- Adjustment of the procedure problems. High pressure, as well as reduced speed injection, can maintain the security of melt flow and avoid wavy lines.

- Raise the mold temperature. With the increase of mold temperature level, the melt fluidity boosts. For crystalline polymer, a higher temperature level contributes to the harmony of formation, so regarding lower the appearance of waviness.

- Adjustment of the dental caries framework. The structure of the mold can likewise cause bumpy lines externally of the product. If the edges and edges of the mold core are prominent, the melt flow resistance is large, which will trigger the instability of the thaw Flow and form wavy lines. Therefore, altering the edges as well as edges of the mold core to make it buffer transition as well as maintain the thaw flow stable can protect against the incident of wavy lines.

- Adjust the thickness of the item. The unequal thickness of the item will certainly make the melt flow resistance larger and also smaller sized, resulting in unsteady thaw flow. The consistent density of the injection mold item can also prevent the look of wavy lines.