TOP 5 CNC Machining Issues, Mistakes and Solutions

CNC machining services are ending up being progressively popular as a result of high accuracy, superior productivity, solid capacity, and also versatility. But when we do not keep it properly or do some incorrect procedures, its efficiency and item quality will certainly be impacted. What is one of the most usual troubles with CNC machines? In this short article, we’ll go over the mistakes in the CNC machining procedure and also exactly how to resolve them.

TOP 5 CNC Machining Issues, Mistakes, and Solutions

CNC machines are beneficial and durable devices made use of to complete various machining operations on the workpiece. The most usual issues in CNC machines are typically utilized by customer mistakes and inadequate upkeep. It’s necessary to determine the issues and also find options to fix these issues. Here we present the most usual CNC machining problems.

Incorrect Devices or Setups

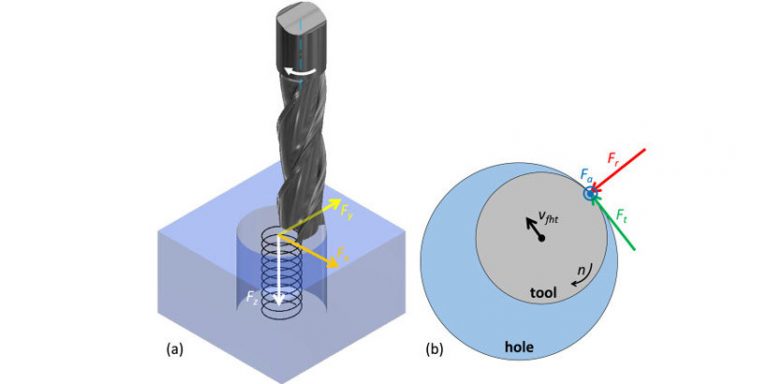

Inappropriate reducing tool, the tool pointer is harmed and not sharp, or improper cutting coolant/lube, these will trigger the inadequate surface area coating on the component and also leave a cutter mark on the product, which speeds up the device wear at the same time.

On top of that, when the feed rate is too low, the component will stay in the course of the cutting device longer than the called for time, leading to the workpiece being burnt. If the feed price is too high or the cutter needs to be changed, it’s easy to leave harsh sides as well as raised marks. Wrong specs may cause burns to devices.

Solutions:

– Replace the tool with a brand-new one if it’s candid

– Pick the right device and also established according to the attributes of the material

– Adjust the setups to correct specification for a particular cutting tool

Programming Errors

CNC machines are managed by computer systems via the program’s language, so there may be some issues due to mistakes in CNC programming. The absence of understanding of G-codes, M-codes, CAD, and also WEBCAM software application, inaccurate programmings such as incorrect setup and information, will result in item errors as well as wrong motion sequencing. These problems can be hard to diagnose for new operators.

Solutions:

– Train brand-new staff members thoroughly as well as properly

– Experienced programmers supervise operations

– Offer in-depth customer handbooks as well as directions to new drivers

– In uncommon situations, just switch off the machine and reboot the system

– Appropriately set up and also align mechanically

Poor Maintenance

If the CNC machines are not cleaned as well as oiled, dust and also particles will certainly be accumulated on the equipment as well as influence the place as well as clamping of components, and the result of the machine then triggers lowered accuracy as well as accuracy. Furthermore, bad result and also clog stop airflow, leading to spindle overheating throughout the process, and also the maker is easy to be harmed.

Solutions:

– Clean and also preserve the machine in use consistently

– Examine degrees of coolants or airflow

Babble or Vibration

The excessive resonance or chatter in the CNC machines will reduce the high quality of the piece, influence the precision of measurements, minimize device life and durability, and even impact the life span of your machine. Babble might strike the work surface or tool, you can pay attention if there is the noise generated.

Solutions:

– Ensure the cut size or deepness keeps deflection below 1/1000th of an inch

– Adjust the RPM of the machining procedure

– Usage balanced device owners when utilizing pin speeds over 8,000 rpm.

Securing Issues

The material blank or workpiece can’t be repaired firmly by the chuck or the fixtures change or shake during the production procedure, this may create the wrong area, the handling is not smooth, the item goes down, and also an accident or various other problems.

Solutions:

– Examine and adjust the hydraulic pump and also the hydraulic stress setup.

– Establish the jaws effectively to hold the material firmly.

– Examine if the lubricating substance is adequate.

– Make certain the item is appropriately positioned.

– Check out other configurations and devices.